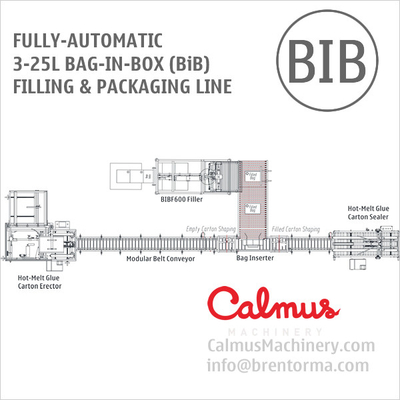

Fully-automatic Bag-in-Box (BIB) Filling and Packaging Line

This China-Made Fully-automatic Bag-in-Box Filling and Packaging Line is especially designed for food packaging and widely used for packaging spring water, post mix syrup, edible oil and beverage. Certainly it also can be used for packaging liquid soap, motor oil, diesel exhaust fluid (AdBlue/DEF), engine coolant. Built in China, but at high quality level.

The filling and packaging line includes:

Bag-in-Box Filler, Carton Erector, Bag Inserter, Carton Sealer, Conveyors and other assistant equipment.

1. Fully-automatic Bag in Box Filling Machine

This Fully-automatic Bag in Box Filling Machine is designed for filling spouted bags with a wide range of liquids like drinking water, post mix syrup coke, edible oil and beverage. It features fully-automatic by employing PLC and touch screen control system. The whole process of continuous bags feed, decapping, vacuumization (optional), nitrogen injection (optional), filling, capping, cutting apart from continuous bags and transiting to the conveyor can be completed automatically, no human operation required.

This filling machine can cap various spigots including Vitop and Scholle's. It is designed with CIP (Clean in Place) function and pipeline connection. Grade 304 stainless steel body and 316L stainless steel fluid-contact parts.

Features:

1) Fully-automatic, WEB type bags fed.

2) Easy to use. The touch-screen control system makes operation easy.

3) An electromagnetic or turbine flowmeter employed improves filling precision and truly achieves the quantitative filling.

4) An air filter employed brings clean air to the filling space.

5) Grade 304 stainless steel body and 316L stainless fluid-contact parts.

6) Filling a different capacity bag acceptable only by changing the setting.

7) Options of vacuumization and nitrogen injection available for specific products use.

Specifications:

Applicable bags: pre-cut continuous module or WEB type bags, spout-fitted, 3-25 litres. (Spout is called Gland or Flange too.)

Filling capacity:

450-510 bags/hour for 5 litres

360-400 bags/hour for 10 litres

250-270 bags/hour for 20 litres

Power: 1.0 kW

Compressed air: 6-8 bar, 500 NL/min

2. Carton Erector (Erecting carton and sealing bottom)

Erecting capacity: 6-7 cartons/min

Grade 304 stainless steel construction

Hot Melt Glue System: Nordson

3. Bag Inserter (Inserting filled bags in cartons)

Inserting capacity: 15 bags/min

Grade 304 stainless steel body

4. Hot Melt Glue Box Sealer (Closing and sealing top)

Sealing capacity: 10 cartons/min

Grade 304 stainless steel construction

Hot Melt Glue System: Nordson

5. Conveying Systems

Grade 304 stainless steel

Absolutely EU quality standard, but less than half of EU price.

Download the BROCHURE.

Calmus Machinery, a division of

Brentorma, is a leading equipment manufacturer in mainland China, who provides complete solutions for the drinking water, beverage and food industry. Our products include bag in box fillers, bag in box packaging lines, packaging equipment, water plant equipment, as well as additional equipment used in the water, beverage and food processing industry.

Contact us today for a competitive price.

---

Contact: Mr. Gavin CHEUNG

Email: info(a)brentorma.com

Tel: +86-755-28033527

---